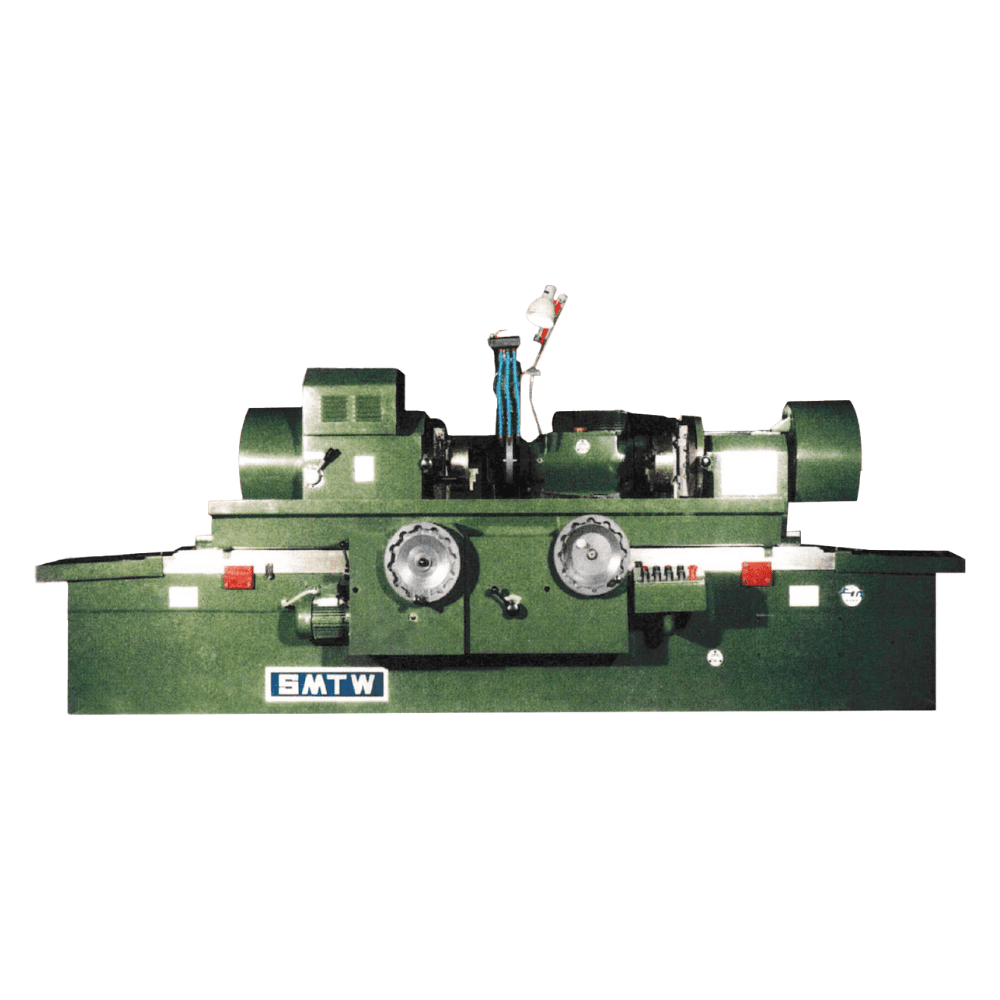

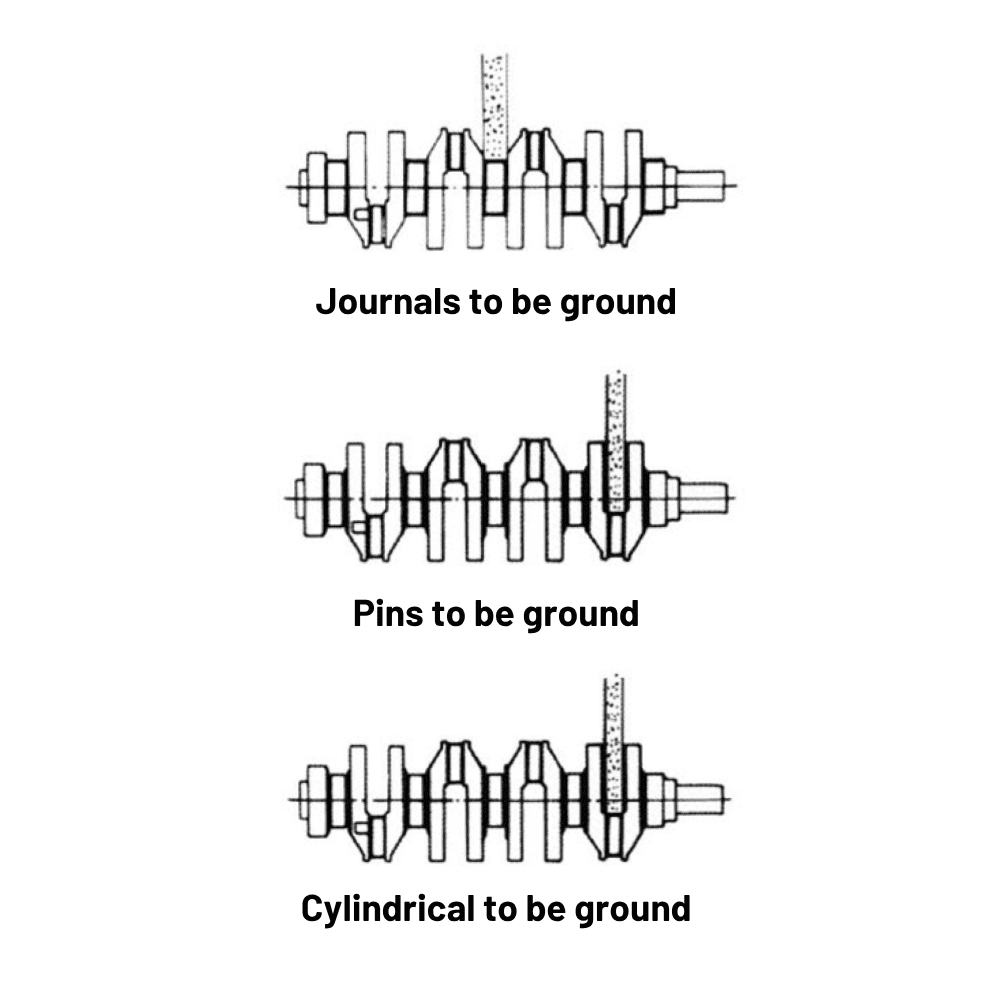

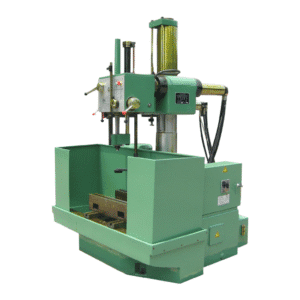

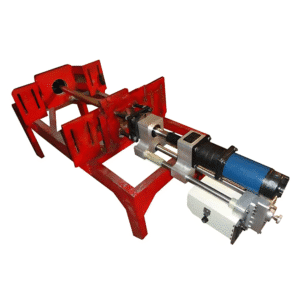

Mesin MQ8260B digunakan di bengkel perbaikan mesin automobiles, traktor, dan mesin diesel untuk proses grinding pada journals (jurnal poros engkol) dan crankpins (pin engkol). Mesin ini menyediakan kecepatan kerja variabel, penyesuaian mudah, dan konstruksi presisi untuk hasil pengerjaan poros engkol yang halus dan akurat.

Fitur Utama:

-

Tersedia tiga kecepatan kerja berbeda melalui sistem belt di headstock; penutup belt dapat dibuka untuk memudahkan penggantian.

-

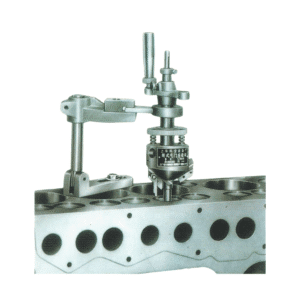

Cross swallow-tailed chucks digunakan (opsional) pada headstock dan tailstock untuk menjaga poros tetap stabil dalam operasi.

-

Kopling gesek (friction coupling) disematkan di rantai transmisi headstock agar penyesuaian lebih praktis.

-

Meja tunggal (single layer table) dengan kemiringan sekitar 10° memungkinkan traverse longitudinal dijalankan secara manual atau otomatis (power feed).

-

Pendekatan cepat (rapid approach & withdrawal) pada wheel head dikendalikan secara hidrolik, dengan tampilan digital resolusi 0,005 mm.

-

Spindle roda (wheel spindle) berdiameter 80 mm, memberikan kekakuan dan kekuatan yang tinggi selama penggerindaan.

-

Wheel head bergerak menggunakan roller ways, yang menghasilkan gerakan halus dan minim gesekan.

-

Jalur bed & wheel head dilumasi otomatis secara siklus melalui pompa oli terintegrasi.

-

Meja bed dilapisi plastik (plastic coating) untuk melindungi permukaan dan mengurangi gesekan serta korosi.

MQ8260B Crankshaft Grinding Machine

| Models | MQ8260B |

| Max. swing over table | 580mm |

| Dia. ground with steady rest | 30-100mm |

| Throw of crankpin | 0-110mm |

| Dia. ground for longitudinal cylindrical grinding | 30-200mm |

| Max. work chucking length | 1500mm (on common chucks) |

| 1390mm (on cross chucks) | |

| Distance between centres | 1600mm |

| Centre height | 300mm |

| Taper of workhead centre | No.5 morse |

| Taper of tailstock centre | No.5 morse |

| Max. weight of work | 120kg |

| General perfomance | |

| Traverse of tailstock sleeve | 30mm |

| Wheel dressing & compensation feed | By hand |

| Auto. intermittent feed | No |

| Auto. plunge-cut feed | No |

| Workhead | |

| Possibility of spindle rotation | Possible |

| Possibility of base plate swivel | Impossible |

| Spindle speed | 25, 50, 100 r/min (for 50Hz) |

| 30, 60, 120 r/min (for 60Hz) | |

| Chuck diameter (3 jaw) | 250mm (common chuck) |

| 200mm (cross chuck) | |

| Wheelhead | |

| Wheel size | 900x40x305mm (Max) |

| 600x40x305 (Worn to) | |

| Spindle speed | 760 r/min (for 50Hz) |

| 760 r/min (for 60Hz) | |

| Max. travel (including rapid travel) | 300mm |

| Max. cross travel on leadscrew | 200mm |

| Rapid travel | 100mm |

| Wheelhead cross travel against the saddle | 70mm (forward) |

| 55mm (backward) | |

| Travel per rev. of handwheel | 1mm |

| Travel per div. of handwheel | 0.005mm |

| Table | |

| Travel per rev. of handwheel | 5mm |

| Max. longitudinal travel | 1600mm (by hand) |

| 1600mm (by power) | |

| Max. swivel of upper table | Clockwise 1°30’ |

| Counter clockwise 1°30’ | |

| Grinding capacity | 580x1600mm |

| Overall dimensions (LxWxH) | 4000x2100x1630mm |

| Net Weight | 6710kg |